Essential Homogenizer Spare Parts for Maintaining Food Processing Efficiency

08 August 2024

Know the essential homogenizer spare parts needed to maintain peak efficiency in food processing. Optimise your operations with Amon Engineering, Melbourne.

Homogenizer spare parts are crucial for maintaining the efficiency and reliability of food processing equipment. As a precision and general engineering services provider in Melbourne, Amon Engineering understands the importance of having access to high-quality spare parts for homogenizer machines. Regular maintenance and replacement of essential components can help prevent unexpected downtime and ensure consistent product quality.

Valves and Seals

The valves and seals of a homogenizer machine are critical components that require regular attention. Over time, these parts can become worn or damaged, affecting the machine’s performance and product quality. Regrinding or replacing the valves is essential to ensure optimal homogenization. Additionally, maintaining the integrity of the seals is crucial to prevent leaks and maintain the desired pressure within the system.

Pressure Gauges

Accurate pressure monitoring is essential for the proper functioning of a homogenizer machine. Calibrating the pressure gauges regularly is crucial to ensure that the machine is operating within the required pressure range. Pressure gauges with stainless steel components and glycol fluid filling are preferred for applications involving milk and other corrosive products.

Belts and Bearings

The belts and bearings of a homogenizer machine are subject to wear and tear over time. Replacing these components is necessary to maintain the machine’s efficiency and prevent unexpected downtime. It is also important to ensure that the lubrication oil and cooling water do not spill into the belt drive, as this can lead to premature wear and damage.

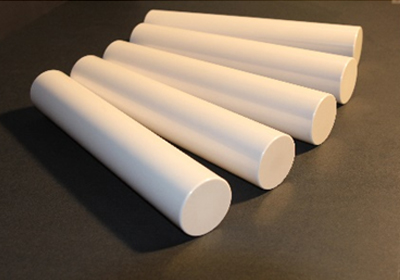

Plungers and Seals

The plungers and seals of a homogenizer machine play a vital role in the homogenization process. These components must be regularly inspected and replaced as needed to maintain the machine’s performance and product quality. Proper maintenance of the plungers and seals can help prevent issues such as leaks and uneven distribution of the product.

Crankshafts and Antifriction Bearings

The crankshafts and antifriction bearings are essential for the smooth operation of the homogenizer machine. These components must be checked for wear and tear and replaced as necessary to ensure the machine’s continued efficiency and reliability.

Why Regular Maintenance with Homogenizer Spare Parts Matters

Homogenizers subject their components to significant wear and tear during operation. Over time, this wear can lead to:

• Reduced homogenization efficiency: Worn parts can compromise the machine’s ability to create a uniform mixture, impacting product quality.

• Increased downtime: Breakdowns caused by failing parts can lead to costly production delays.

• Higher energy consumption: Inefficient homogenization due to worn parts can result in increased energy usage.

By proactively replacing essential homogenizer spare parts, you can:

• Maintain optimal homogenization performance: Consistent quality and texture are assured for your food products.

• Minimise downtime: Regular maintenance reduces the risk of unexpected breakdowns, keeping your production lines running smoothly.

• Reduce operational costs: Timely replacement of spare parts prevents unnecessary wear and tear on other components, leading to lower long-term costs.

Amon Engineering: Your Partner for High-Quality Homogenizer Spare Parts

At Amon Engineering, we pride ourselves on our expertise in precision and general engineering services. We understand the importance of homogenizer maintenance and can provide you with high-quality spare parts and expert advice to help you maintain your food processing efficiency.

Optimized by www.NetwizardSEO.com.au