Engineering Plastics in High-Tolerance Manufacturing: Precision and Durability Combined

20 March 2025

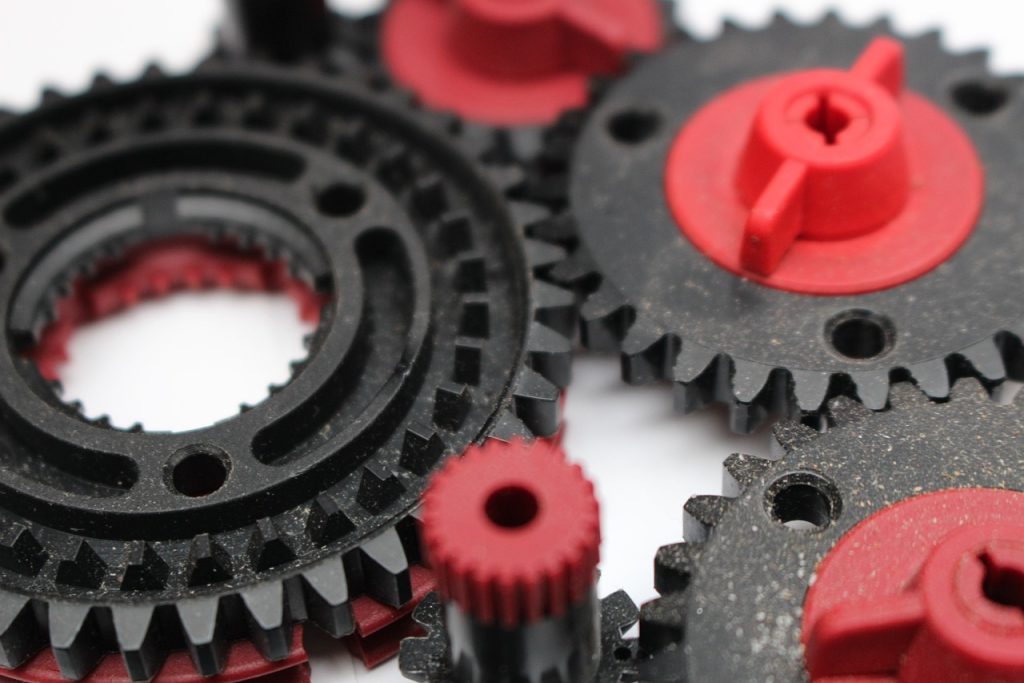

High-tolerance manufacturing relies on Amon Engineering’s advanced engineering plastics for precision, durability, and reliable performance.

Engineering plastics present an effective solution for industries demanding high-tolerance components with increased durability. A broad spectrum of mechanical properties, thermal resilience, and resistance to chemicals renders these materials suitable for critical manufacturing processes. Enhanced operational lifespans and refined performance metrics are achievable through their implementation, marking their importance in maintaining exacting standards.

Engineering Plastics vs. Traditional Materials: A Performance Comparison

Conventional materials, such as metals and wood, often fall short in applications requiring a balance between lightweight and high strength. Conversely, advanced polymers offer greater design flexibility, enabling complex geometries and part consolidation, leading to reduced assembly costs and improved functionality. This makes engineering plastics ideal for complex designs where traditional materials would be too heavy or difficult to form.

Traditional materials can pose challenges in corrosive environments; however, durability is readily attainable using advanced plastics. Chemicals and weathering are easily resisted through these materials, ensuring a longer service life and reduced maintenance, thereby providing a tangible economic advantage over traditional alternatives. Unlike metals, engineering plastics do not rust and offer superior chemical, wear, and corrosion resistance.

Material Properties That Make Engineering Plastics Ideal for Precision Work

Dimensional stability stands as a vital characteristic, ensuring components maintain their shape and size under varying temperatures and loads. Tight tolerances and consistent performance across a wide range of operational conditions become reliably attainable.

Inherent vibration-damping capabilities offer another advantage, minimising noise and wear in high-speed machinery. Enhanced overall equipment effectiveness and a safer working environment are facilitated, leading to smoother, quieter operations.

Mouldability offers another significant benefit, allowing for the creation of complex parts with intricate details. This capability, readily achievable with advanced polymers, facilitates design innovation and functional integration, resulting in more efficient and streamlined products.

Common Applications of Engineering Plastics in High-Precision Industries

Advanced polymers find extensive use across various sectors. Their unique properties make them ideal for components requiring both precision and durability. Industries benefit significantly from incorporating these materials into demanding applications.

• Automotive: Weight reduction and enhanced fuel efficiency are obtained through components like gears, bushings, and fuel system parts.

• Aerospace: High-performance applications such as aircraft interior panels and structural components benefit from the lightweight strength of these materials.

• Medical Devices: Biocompatibility and sterilisation resistance are essential for surgical instruments, diagnostic equipment, and implantable devices.

• Electronics: Insulation, heat dissipation, and dimensional stability are readily attained in connectors, housings, and circuit board components.

• Industrial Equipment: Gears, bearings, seals, and pump components benefit from the wear resistance and chemical inertness of these materials.

• Consumer Goods: Durability and aesthetic appeal are crucial for power tools, appliances, and sporting goods.

• Telecommunications: Signal transmission, weather resistance, and structural integrity are necessary for fibre optic connectors, antenna components, and network infrastructure.

Given the demand for precision components, Amon Engineering delivers custom solutions using engineering polymers, ensuring clients receive components that meet stringent performance criteria. Servicing diverse industries with precision-engineered plastic components forms the core of our expertise, allowing us to meet various complex tooling needs.

Discuss your project needs with Amon Engineering and discover the potential range of precision components in a wide material selection.

Optimized by www.NetwizardSEO.com.au